|

Quick

links to Pump Products Information: |

| Pump Speed Performance Ranges |

| Corrosion Resistant Heavy Duty Centrifugal Pumps |

| Pump Arrangements |

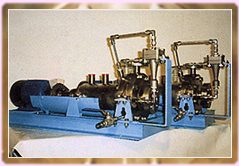

| The

AVONPUMP range of open impeller centrifugal

pumps has specific applications in handling corrosive, erosive and difficult

liquids which are not easily dealt with by the more conventional pumps

available. Pumps are available in various configurations. In the horizontal format we provide both close coupled and long coupled, either of simple construction or with back pull out facility. In addition a self priming version can be supplied, our self priming system utilises the twin tank system. Vertical pumps with shaft lengths (below the support plate) up to five metres can be supplied. Pontoon mounted pumps can also be supplied.  AVONPUMPS

are available in most metals and engineering plastics, plastic bodied

pumps are encased in a robust steel housing. For stability in the shaft

seal area we prefer to provide plastic bodied pumps with metallic shafts

and impellers, although if metal contact surfaces are mandatory we can

produce plastic covered impellers and shaft ends. AVONPUMPS

are available in most metals and engineering plastics, plastic bodied

pumps are encased in a robust steel housing. For stability in the shaft

seal area we prefer to provide plastic bodied pumps with metallic shafts

and impellers, although if metal contact surfaces are mandatory we can

produce plastic covered impellers and shaft ends.Pump end materials are chosen for the particular duty, and may be made from , or a combination of, Stainless steels (316 and 304), Titanium, Hastelloy's, Monel's, Nickel alloys, bronzes and aluminium, with non-metallic builds in polypropylene, PVDF and PTFE. Normally we fit mechanical shaft seals, these can be from any major seal producer. (Some Clients specify a particular make to give uniformity at site) Choice and arrangement of seals, single, double or tandem is based on our, and the seal manufacturers, experience for the particular application. Packed glands can also be provided if specified by the client. On the long coupled pumps up to 120 deg Centigrade the bearing bracket is cast iron with ball and roller bearings, oil lubricated and provided with a constant level oiler with oil retention by lip seals. Over 125 deg we offer cooled bearing brackets fabricated from stainless steel, cooling is by a coolantjacket with the possible addition of a cooling fan mounted on the coupling. Motors and couplings are any Major manufacturer, normally we fit Brook Hansen motors and Metastream or Neupex couplings. A steel guard is normally fitted sparkresistant guards are available at extra cost. Baseplates are robust steel fabrications and include an integral drippan. Depending on size lifting points are fitted. API bases are available at extra cost. All pump and base steel/iron work is finished in AVONPUMP standard offshore epoxy, 75 microns DFT. Other paint systems can be provided at extra cost. Motors are in their makers standard finish. Bolting is stainless steel. Housing gaskets are either PTFE or spiral wound metal/ptfe depending on the application.  All

AVONPUMPS are subjected to works tests

comprising an unwitnessed hydrotest and an unwitnessed performance test

at 50 hz speed. If the pumps are being supplied as `bare shaft units'

or if client is to supply and fit the motor at site, we will test with

a slave motor. All performance test results are converted to motor nameplate

speed from the test speeds. All

AVONPUMPS are subjected to works tests

comprising an unwitnessed hydrotest and an unwitnessed performance test

at 50 hz speed. If the pumps are being supplied as `bare shaft units'

or if client is to supply and fit the motor at site, we will test with

a slave motor. All performance test results are converted to motor nameplate

speed from the test speeds.Other tests such as NPSH, Vibration and Noise are available at extra cost, as are tests witnessed by the client or his representatives. Because of our open impeller design, rotating in a concentric housing, with generous clearances AVONPUMP efficiencies are somewhat lower than those of conventional pumps with shrouded impellers and volute housings. Thus for routine duties where corrosion or erosion is not a problem we would not be competitive on price or power with mass produced pumps. AVONPUMPS fill the gaps where corrosion, erosion, low npsha and non standard applications arise. |

AVONPUMPS

are full process open impeller pumps, available as horizontal centrifugal

pumps with centre line discharge or arranged for vertical installation. AVONPUMPS

are full process open impeller pumps, available as horizontal centrifugal

pumps with centre line discharge or arranged for vertical installation.Pump ends are available in many corrosion resistant, erosion resistant, high temperature and low temperature materials - both metallic and non-metallic. In addition AVONPUMPS can be fitted with jacketted housing, cooled bearing brackets, cooled seals and other special features. AVONPUMPS are of robust construction with the wetted ends usually machined from block of the specified material. Some pumps with non-metalic housing have steel/iron reinforcement whilst pumps with ends in expensive materials such tantalum are constructed with the corrosion resistant lining fabricated into a steel/iron casting. Impellers are of mulibladed, open ytpe with generous clearances and have the capacity to handle entrained vapours, particles and other debris. Inducers are available for low NPSH applications. AVONPUMPS can be supplied to any degree to trim from bare shaft units (pump end, seal and bearing bracket only) to full process specification including: pump end, seal, bearing bracket, spacer coupling, guard, base, drip try and seal harness. Centre line mounted pumps are also available. |

|

|

|

**

The Seal Chamber is normally stainless steel but can be in other materials

depending on the nature of the Seal flush liquor. * Denotes the corrosion resistant material supplied for a particular duty and can be any of, or combination of the materials listed below the table in red and black. |

|

|

|

||||||||||||||||||||||||||||||||||||

| AVONPUMPS are available in the following arrangements: | |

| Close coupled to motor. Pump and motor only | |

| Close coupled to motor on base with back pull out facility: pump, motor and base | |

| Simple pedestal: pump, non-spacer coupling, guard, base and motor | |

| Back pull out pedestal: pump, spacer coupling, guard, base and motor | |

| Centre line support: pump, spacer coupling, guard, base and motor | |

| Vertical in-line: pump and motor | |

| Vertical in-line `Back pull out': pump, bearing bracket, spacer coupling and motor | |

| Vertical suspended: pump, motor, support plate, support column with bearings | |

| Vertical cantilevered': pump, motor support plate, support coloumn. No bearings in liquid | |

|

|

||||||||||||||||||||

| The coding of AVONPUMP type reference gives the main characteristics of the pump. | |

| The first letter gives the construction (always horizontal unless specified by 'V' for Vertical). | |

| The first number gives the AVONPUMP suction diameter. | |

| The second number gives the AVONPUMP impeller diameter. | |

| The final letter(s) give the material. | |

| First letter(s): | |

| C = Pump end in two or more materials | SP = Pump is self priming |

| F = Pump has fabricated (lined) housing | T = Pump end in one material |

| H = Pump is for high temperature applications | V = Pump is vertical |

| S = Pump meets a special requirement | |

|

|

||||||||||||||||||

| For example: | |

| T2-10S

pump is all stainless construction with 2in (50mm) suction and l0in (250mm)

maximum impeller. C4-l4TR pump has a titanium shaft and impeller in a rubber lined steel housing with 4in (100mm) suction and l4in (350mm) maximum impeller. F6-20H pump has a fabricated Hastelloy, in steel, construction with 6in (150mm) suction and 20in (500mm) impeller. |

| NOTE: | |

| For pumps to BS 5257 and DIN 24256, the Avon numbering will be replaced by the BS/DIN reference, for example: T50.32.250 T pump has an all titanium pump end with 50mm diameter suction, 32mm diameter discharge and a 250mm nominal impeller. |

| Camaction Avonpump Spares Limited |

| Avonpump Home Page | Products | Services | Contact Us | About Us |

| The Farthings, 11 Arnor Close, Worle, Weston-super-Mare, Somerset, BS22 7GB Tel: +44 (0) 1934 520091 Fax: +44 (0) 1934 513062 Email: enquiries@camaction.org.uk |